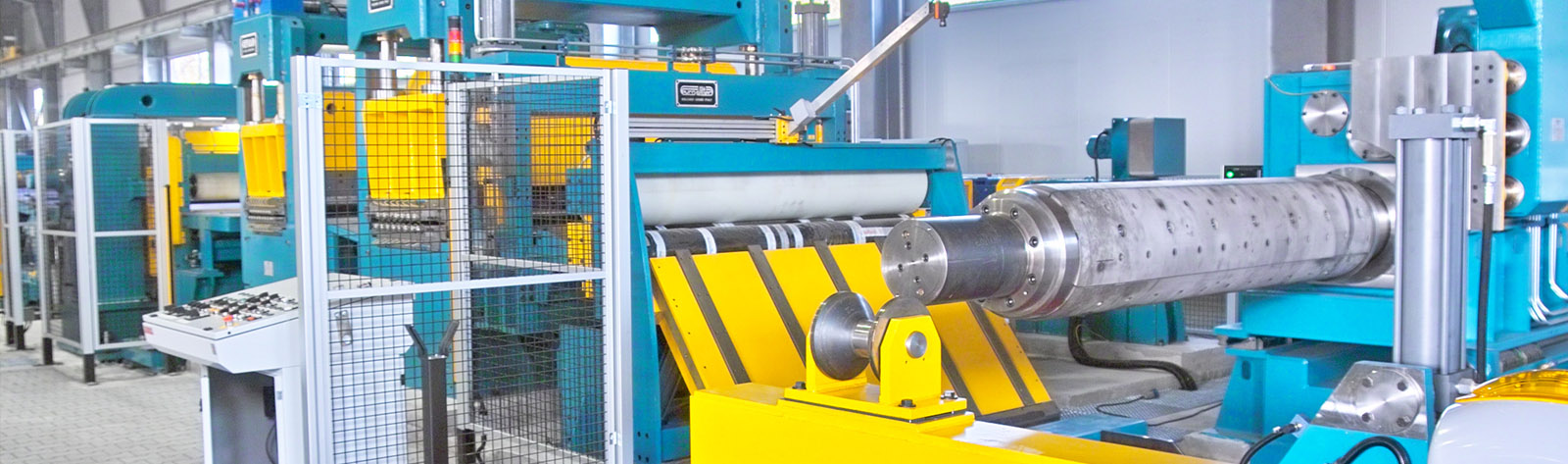

Line ACP I for cross cutting

Line technical parameters

Sheet metal parameters

Maximum coil weight 35 t

Cutting material width range [300]*400 – 2 100 mm

Cutting material thickness ranges (cold-rolled sheets) 0,4 – 3,0 mm

Cutting material thickness ranges (hot-rolled sheets) 1,0 – 6,0 mm

Sheet length range [300]*400 – 6000 mm

Tolerance in sheet length 0,5 mm / 1 mb

Sheet flatness according to EN norm

Sheet flatness with narrower tolerances Tesko Steel LaserPrec® lub LaserPrec®Plus

* dimensions on request and for final confirmation by the technology department

Technology

All processes are tracked by automated lines. Both the cutting tolerance (0.1 mm) and the force and the surface after cutting, which is further checked by the laser that automatically rejects sheets that do not meet flatness standards and dimensions set prior to cutting. The laying process is conducted automatically in a wrapper machine while the process of weighing the finished material after cutting is performed on digital scales installed in the machine's packer.

We are able to guarantee the highest quality of the material after cutting both cold- and hot-rolled sheets.

Production capabilities

The line is able to cut up to 8-10 thousand tons of material with the parameters listed above on a monthly basis.